iBalancer represents a new era in industrial balancing software. It is equipped with powerful algorithms that simplify complex analyses and ensure high accuracy in static and dynamic balancing operations. Thanks to its user-friendly structure, operators can manage challenging processes quickly and without errors.

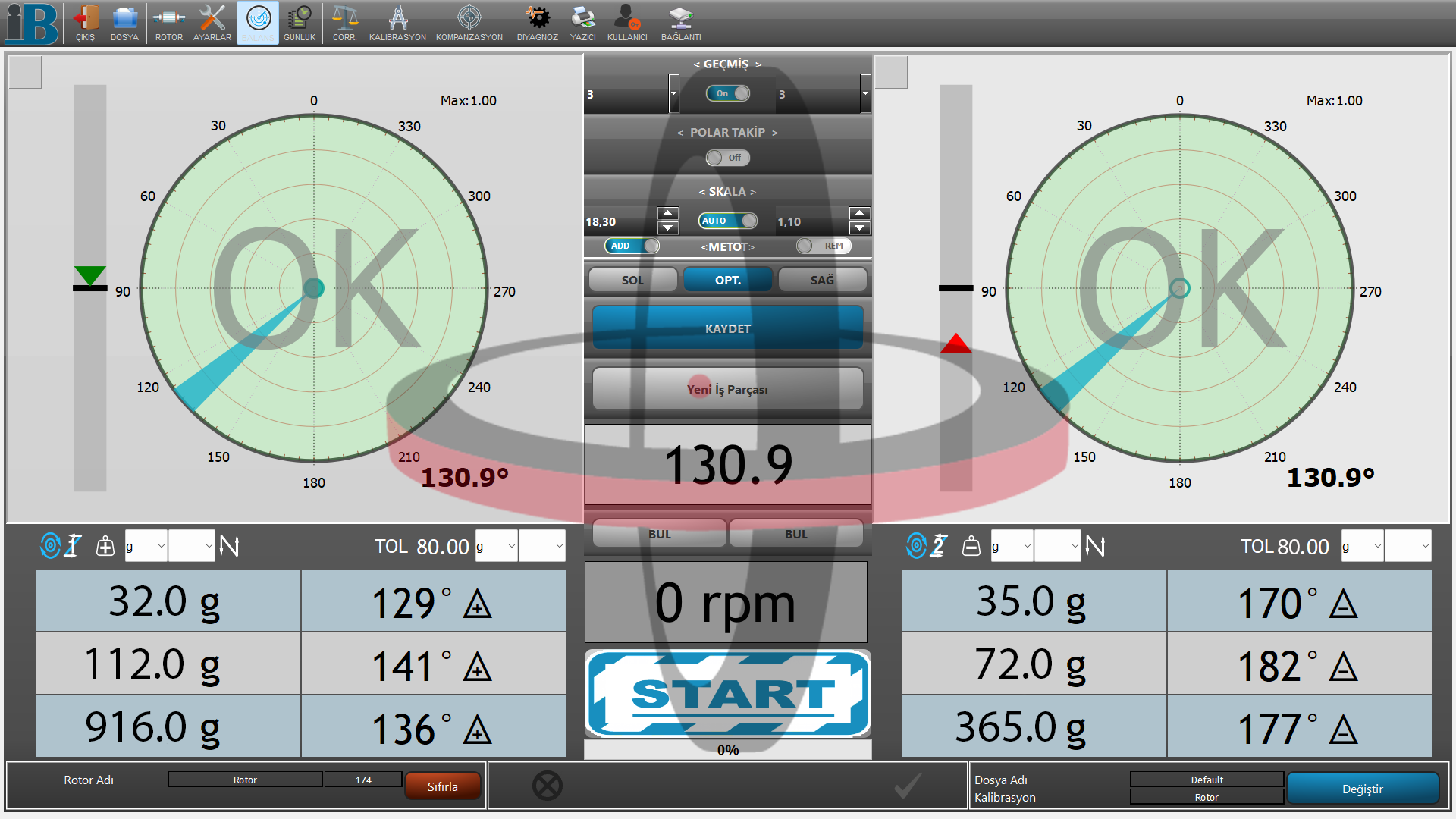

Advanced Measurement Technology

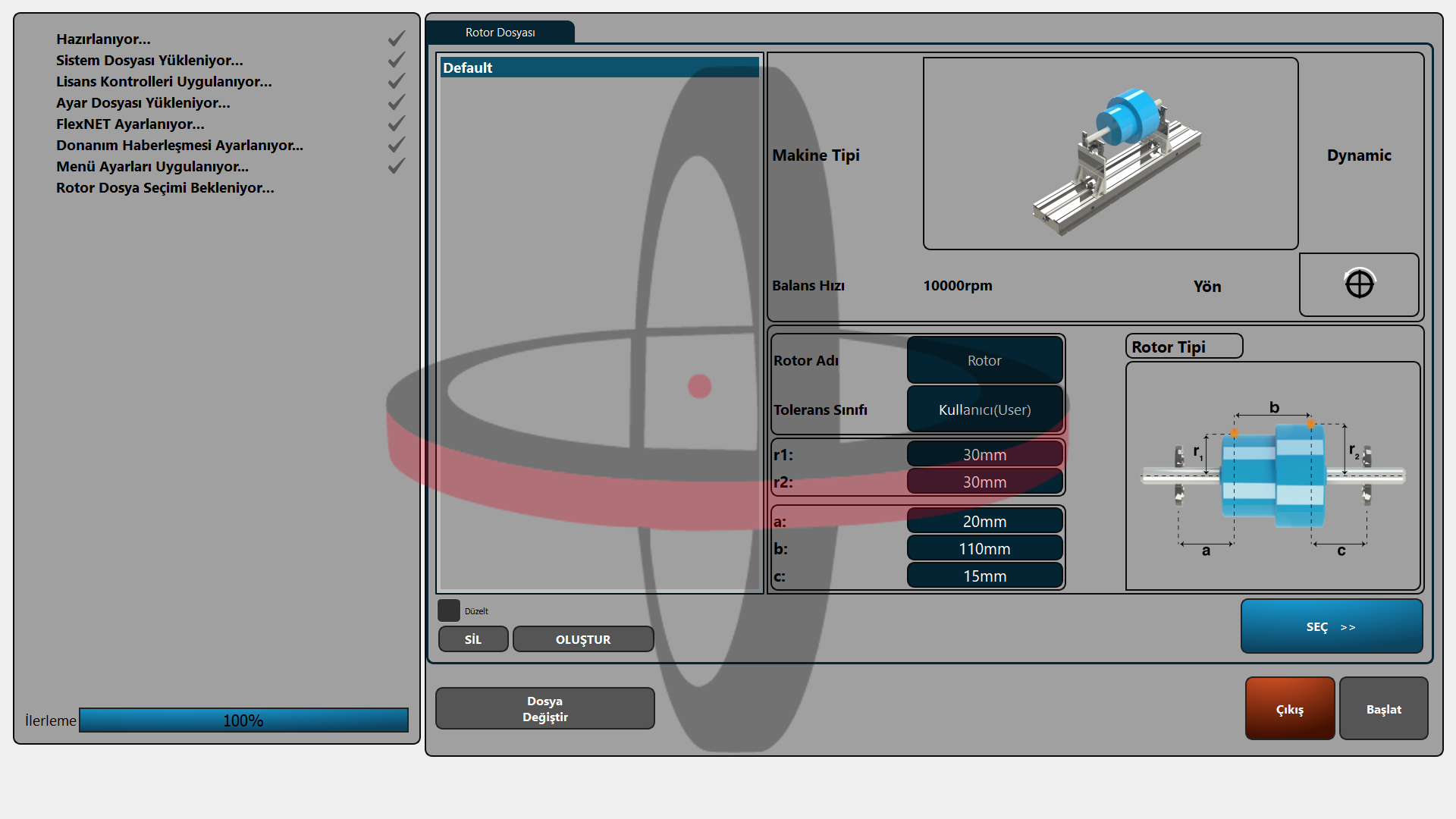

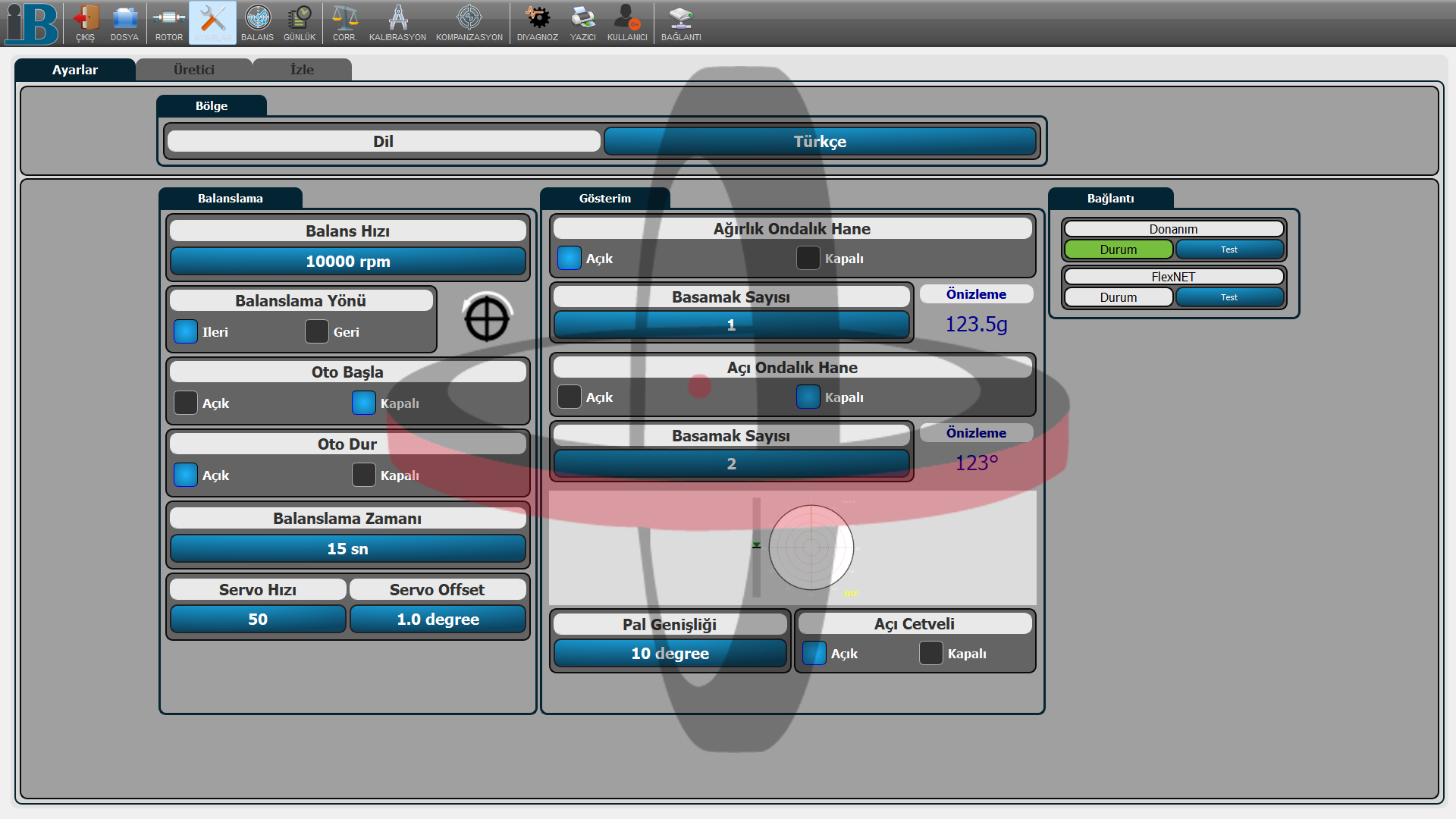

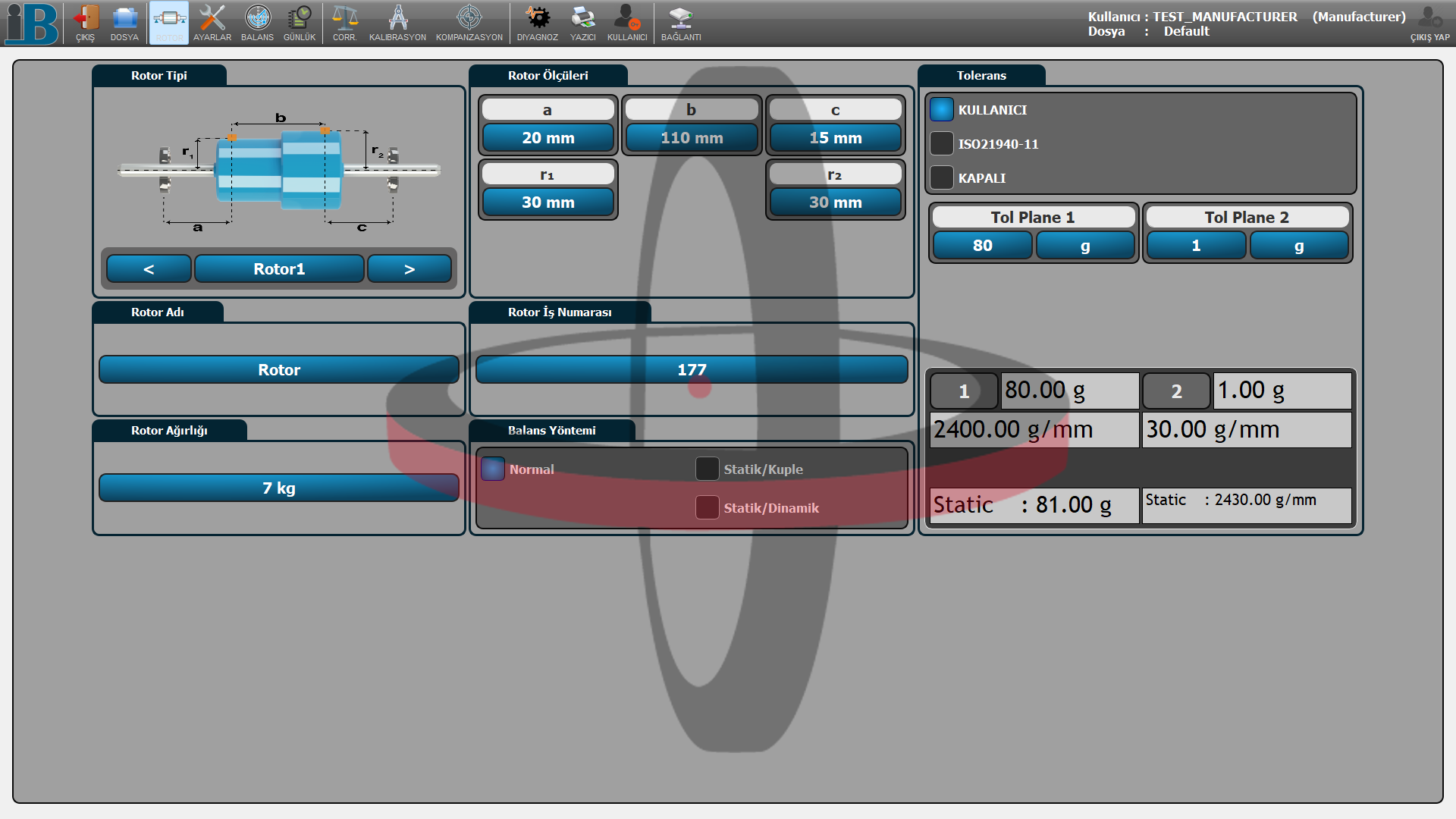

iBalancer performs high-precision measurements in single- or double-plane systems. It maintains consistent stability when balancing various components such as rotors, shafts, pulleys, fans, impellers, or brake discs. Dynamic measurement modes instantly analyze vibration and oscillation values, clearly identifying the source of errors.

Speed and Efficiency

The most common losses in production processes occur during calibration and rebalancing processes. The calibration-free operation offered by iBalancer eliminates the need for re-adjustments for each workpiece. This ensures continuity in the production line and reduces labor costs.

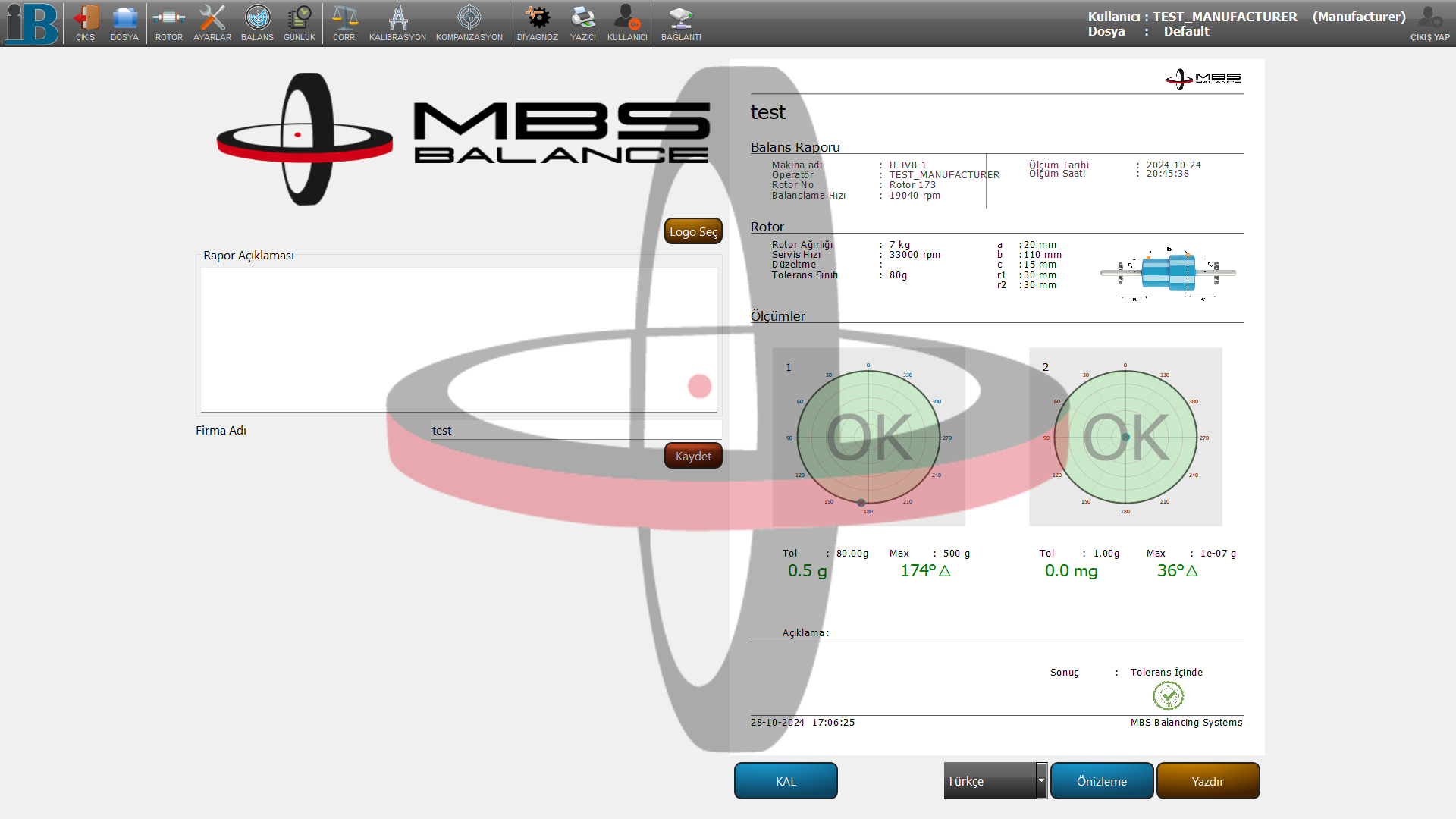

Reporting and Traceability

One of the standout features of iBalancer is its detailed reporting infrastructure. Measurement results can be instantly viewed on the operator's screen and exported in PDF or digital format. This makes quality control processes transparent, and documents that comply with international standards can be easily prepared for customer deliveries.

User Experience and Support

The interface, with its simple and multilingual (Turkish/English) structure, is easily usable by operators of all skill levels. Thanks to 24/7 remote access support, you can receive uninterrupted technical support from software installation to daily maintenance.

Who is it for?

- High efficiency in mass production lines for automotive and sub-industry manufacturers

- Fast and accurate balancing for maintenance and repair shops

- Detailed analysis and reporting for R&D laboratories

iBalancer is a powerful software that, with its reliability and speed, is poised to become the new standard in modern industrial balancing.