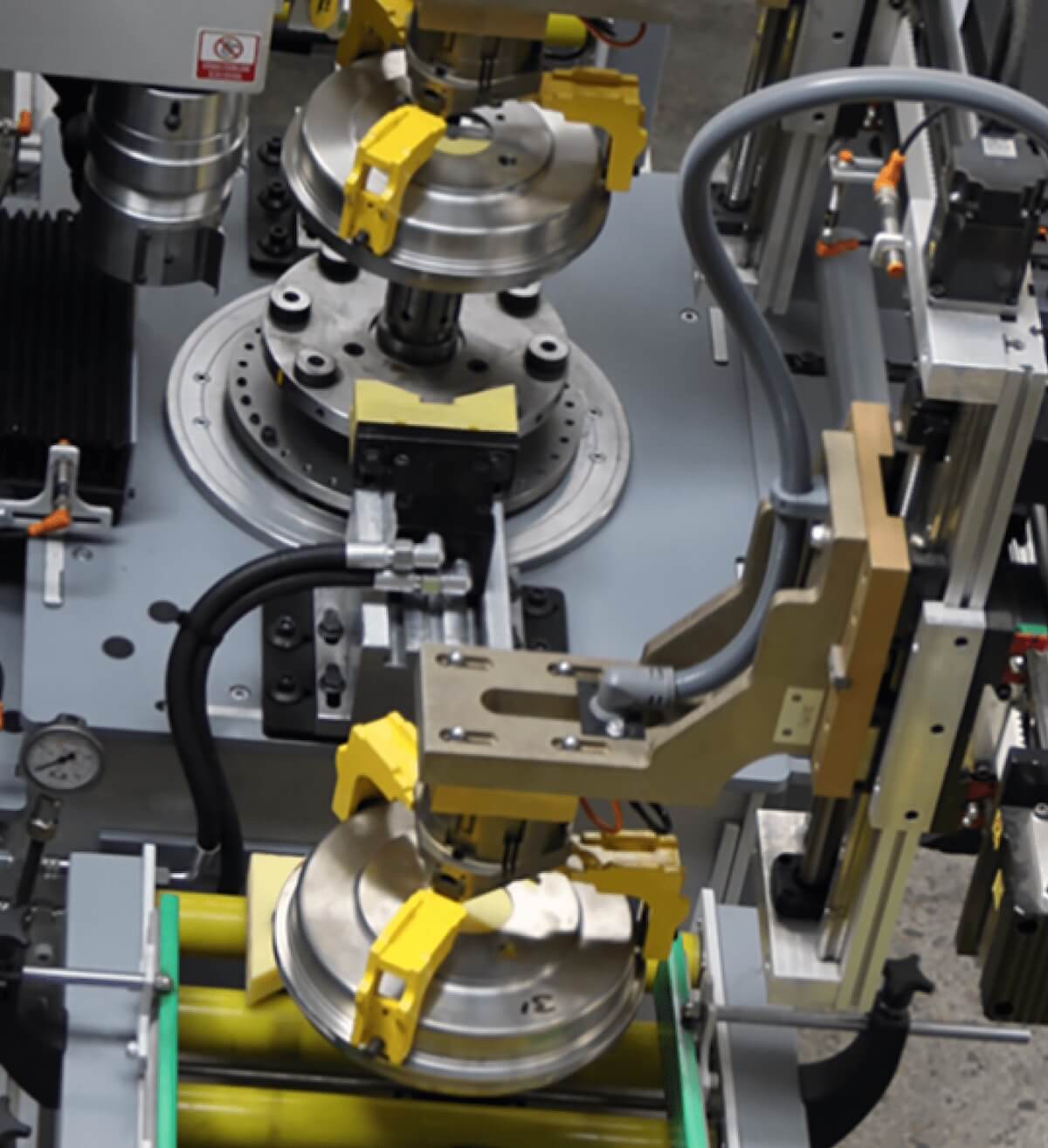

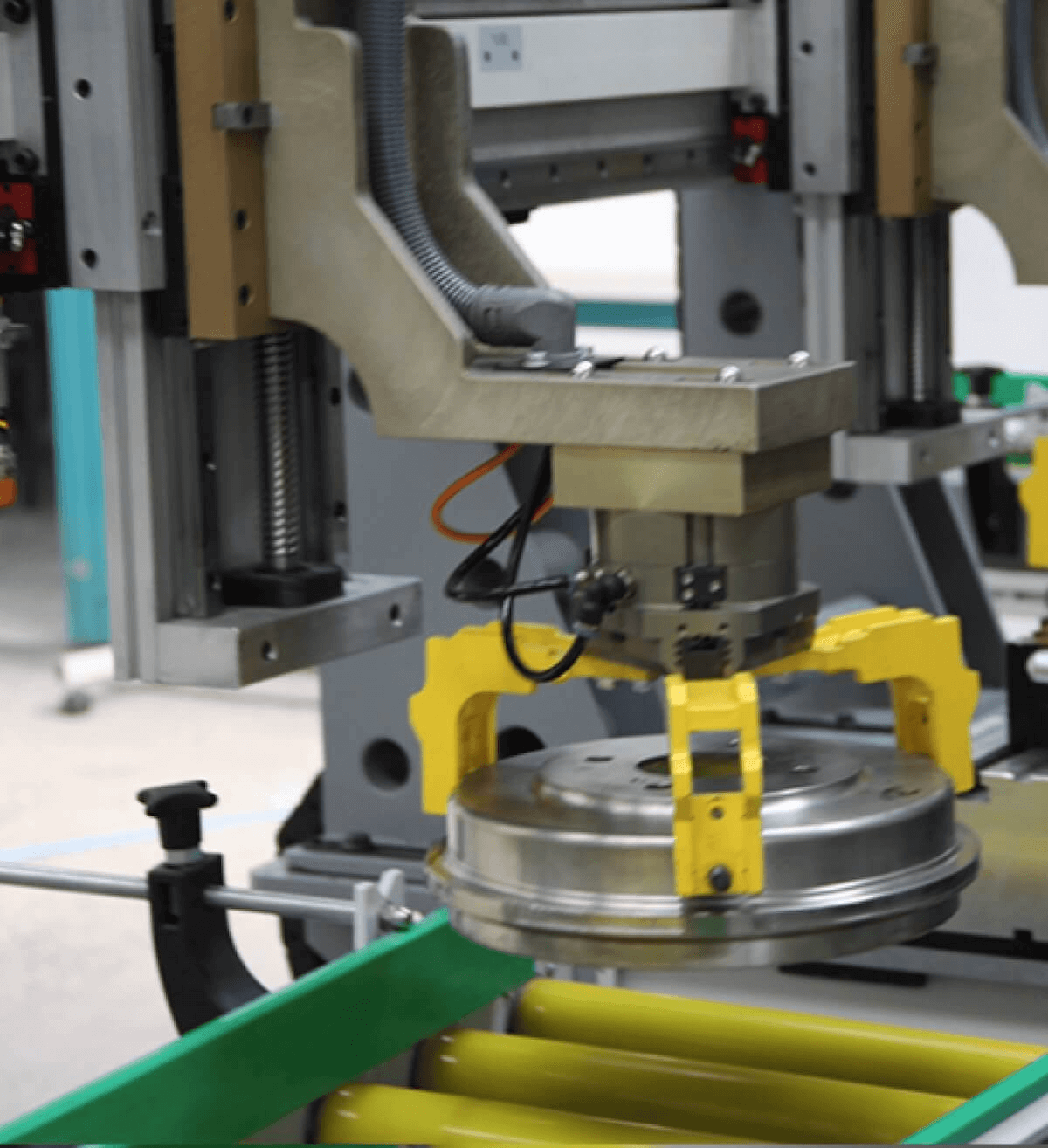

Robot Carrier

Product Description

Robotic Support for Uninterrupted Production

A Robotic Carrier is a system that ensures parts to be balanced are quickly and safely loaded into and unloaded from the machine, allowing the next part to be loaded. This automation makes it possible for mass production to continue without interruption, saving time and labor.

The designed robotic carriers are customized according to the technical specifications of the parts to be balanced. The system is delivered with software prepared to meet the needs of your production line. Supported by 5-6 bar of air pressure for operation, the robotic carrier optimizes production processes with high efficiency and precision.

Application Areas

- Automatic loading and unloading in CNC balancing machines

- Operational continuity in mass production lines

- Large-scale industrial production processes

- Increased production efficiency by reducing the need for operators

- Balancing operations that require high precision

Why a Robotic Carrier?

Discover the standout features of the Robotic Carrier:

- Saves time and labor in production processes

- Provides uninterrupted and fast automation support

- Customizable structure suitable for different production lines

- High precision and efficiency

Product Gallery