What is Balancing? Its Critical Importance in Production and Safety

In industrial processes and in our daily lives, balancing is of vital importance for all types of rotating equipment or components to operate smoothly and efficiently. Balancing refers to the condition where the center of mass of a rotating body coincides with its axis of rotation. If the mass distribution of a rotating part is not uniform, meaning the center of mass deviates from the axis of rotation, this condition is called unbalance. Unbalance leads to the uneven distribution of centrifugal forces during rotation, causing vibrations, noise, and wear. This not only shortens machine lifespan but also reduces operational efficiency. Therefore, proper balancing forms the foundation for equipment to operate in a long-lasting, safe, and cost-effective manner.

Unbalance is a problem encountered not only in industrial machinery but across a wide range of applications, from the automotive sector to household appliances. For example, unbalanced wheels in a vehicle can cause steering vibrations at high speeds, irregular tire wear, and reduced driving comfort. In industrial settings, an unbalanced fan, pump, or turbine can lead to serious failures, production losses, and even occupational safety risks. For this reason, understanding what balancing is and recognizing its importance is an integral part of modern engineering and manufacturing practices.

What Does Balance Adjustment Mean and Why Is It So Important?

Balance adjustment is the process of detecting mass imbalance in a rotating component and eliminating this imbalance by adding or removing weight as necessary. This process optimizes the mass distribution around the axis of rotation to minimize unwanted vibrations and forces generated during operation. Balance adjustment is divided into two main categories: static and dynamic balancing. Static balancing eliminates mass imbalance in a single plane, while dynamic balancing corrects mass imbalances in multiple planes and is especially critical for components rotating at high speeds.

The importance of balance adjustment can be evaluated from several perspectives. First, machines that operate in balance produce less vibration, reducing the load on bearings, housings, and other mechanical components. This significantly extends machine life and lowers maintenance costs. Second, vibrations caused by unbalance lead to energy loss. A properly performed balance adjustment improves energy efficiency and helps reduce operating costs. Third, especially in precision manufacturing processes, unbalance can negatively affect product quality. Properly balanced equipment ensures the production of higher-quality products. Finally, excessive vibrations can cause noise pollution in the work environment and create occupational safety risks. Balance adjustment minimizes these risks, providing a safer and more comfortable working environment.

How Do Balancing Machines Work?

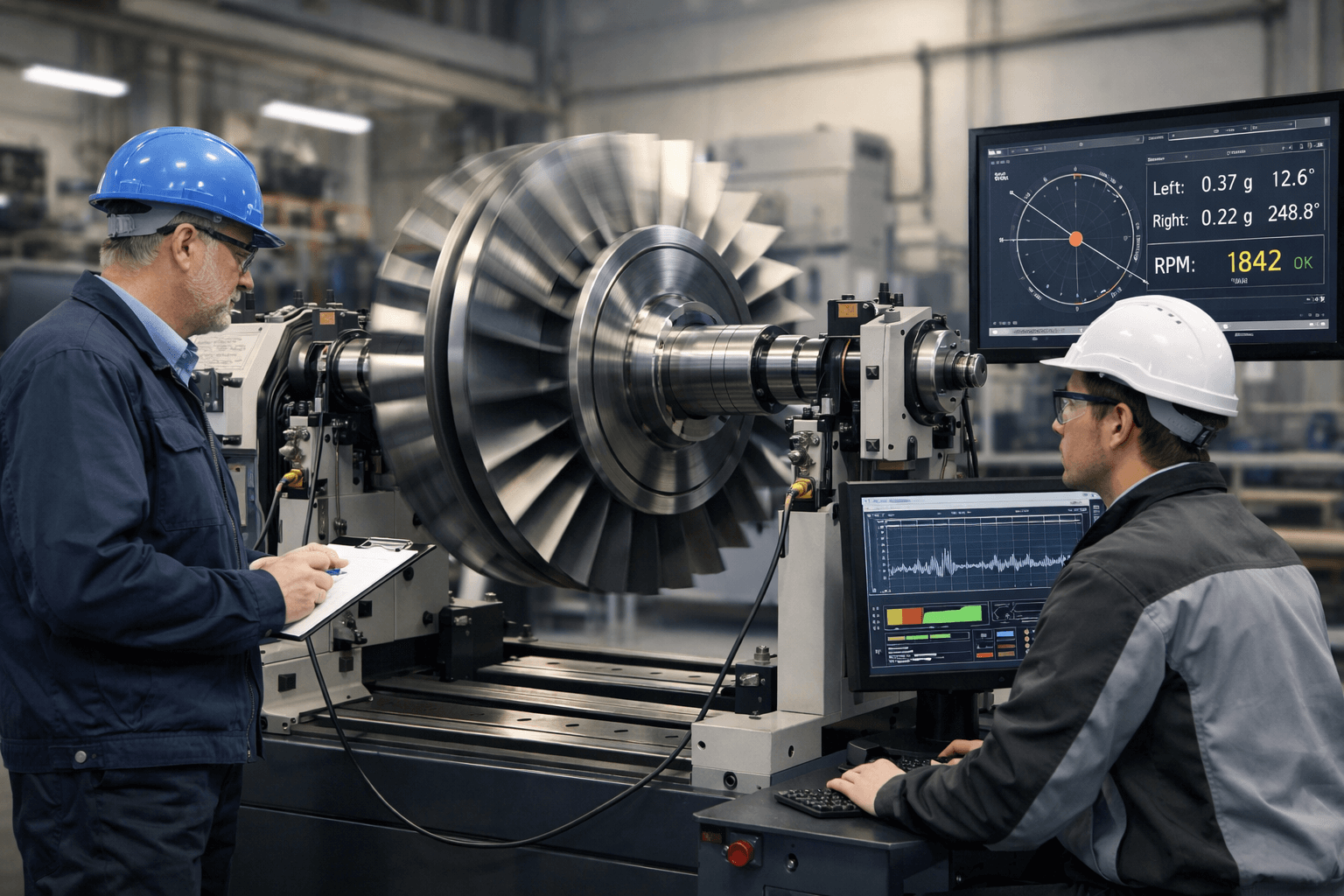

Balance adjustment operations are carried out using specially designed balancing machines. These machines use advanced sensors and software to precisely measure imbalance in rotating components and determine correction points. Basically, a balancing machine operates through the following steps:

- Component Mounting: The part to be balanced is carefully mounted onto the rotating shaft of the balancing machine or onto special adapters. Proper and secure mounting is critical for accurate measurement.

- Rotation and Vibration Measurement: The machine rotates the component at a specified speed. During rotation, vibrations caused by imbalance are detected by sensitive sensors (typically piezoelectric sensors) on the machine. These sensors measure the amplitude and phase angle of the vibration.

- Data Analysis: Data from the sensors is analyzed by specialized software in the machine’s control unit. As a result of this analysis, the amount of imbalance (in grams) and its angular position on the component (in degrees) are determined. Modern balancing machines present this data visually, making the operator’s job easier.

- Correction Process: The required amount of weight is added to the imbalance points identified by the software (usually by welding, bolting, or using special balancing weights), or material is removed from the component (by drilling, grinding, etc.). This correction process aims to align the center of mass with the axis of rotation.

- Verification and Re-measurement: After correction, the balance of the component is re-measured to ensure it is within the desired tolerances. If necessary, the process is repeated. This iterative process ensures the component reaches optimal balance.

Balancing machines are produced in two main types: horizontal and vertical. Horizontal balancing machines are used for balancing long and cylindrical parts (shafts, rotors, fans), while vertical balancing machines are ideal for disc-shaped or short-shaft components (brake discs, flywheels). Both types are designed to provide high precision and efficiency in industrial production.

What Happens If Balance Adjustment Is Faulty? Potential Risks and Solutions

Faulty balance adjustment leads to a range of negative consequences for both industrial equipment and vehicles. These issues can range from minor discomforts to serious failures and safety risks. The main problems caused by imbalance include:

- Increased Vibration and Noise: Imbalance causes excessive vibrations and disturbing noise in rotating parts. This reduces workplace quality and may lead to long-term hearing health issues.

- Reduced Machine Lifespan: Continuous vibrations create excessive stress on bearings, housings, shafts, and other mechanical components. This leads to early wear and fatigue, significantly shortening machine life and requiring frequent part replacement.

- Energy Loss and Inefficiency: Vibrations caused by imbalance convert energy into heat, resulting in energy loss. This causes equipment to consume more energy and increases operational costs. A properly balanced system operates more efficiently with less energy.

- Decreased Product Quality: In precision production processes, vibrations caused by imbalance can negatively affect the quality of manufactured products. For example, imbalance in a lathe can degrade surface finish or cause dimensional inaccuracies.

- Safety Risks: Severe imbalance can cause rotating parts to move uncontrollably or become dislodged, leading to serious workplace accidents. This risk is even greater in large industrial equipment operating at high speeds. Therefore, balance adjustment is a critical safety measure.

- Increased Fuel Consumption (in Vehicles): In automobiles, improper balance adjustment leads to irregular tire wear and negatively affects road handling, causing the engine to work harder and increasing fuel consumption.

To minimize these risks, it is essential that rotating equipment undergo periodic balance inspections and necessary adjustments. Modern balancing technologies and specialized services provide effective solutions to prevent these issues. Balance adjustment is not just a maintenance task, but a strategic investment in production quality, operational efficiency, and occupational safety.

How Much Does Balancing Cost? Pricing and Return on Investment

The cost of balance adjustment services varies depending on the scope of the work, the type and size of the equipment, and the technology used. In the automotive sector, wheel balancing is generally an affordable service, with prices in 2026 typically ranging between 400 TL and 1,200 TL. However, industrial balancing services involve much larger and more complex machines, so costs can increase significantly depending on equipment specifications and required precision.

Factors affecting pricing in industrial balancing services include:

- Equipment Size and Weight: Balancing large and heavy components requires larger and specialized balancing machines, increasing cost.

- Type of Balancing: Static balancing is generally more affordable, while dynamic balancing is more complex and therefore more costly.

- Precision Requirements: Some industrial applications require extremely high balancing precision, which may demand more time and specialized equipment.

- On-site Balancing: In some cases, it may not be possible to dismantle equipment and transport it to a balancing workshop. On-site balancing services are then provided, which are usually more expensive.

- Additional Services: Services such as vibration analysis, bearing inspection, and coupling alignment can affect the total cost.

It is more accurate to view the cost of balance adjustment not as an expense but as an investment. A properly performed balance adjustment provides much greater long-term savings. Benefits such as extended machine life, reduced maintenance and repair costs, improved energy efficiency, enhanced production quality, and ensured occupational safety more than offset the balancing expense. Therefore, the return on investment (ROI) for balancing services is generally very high and represents a critical step for sustainable business success.

Frequently Asked Questions (FAQ)

How often should balance adjustment be performed?

For automobiles, it is generally recommended to check balance adjustment every 10,000–15,000 kilometers or together with tire changes and wheel alignment services. For industrial equipment, the interval varies depending on operating conditions, criticality, and manufacturer recommendations. Balance checks are typically included in periodic maintenance programs.

How is imbalance detected?

Imbalance is detected using balancing machines or on-site vibration analysis devices. These devices measure vibration amplitude and phase angle to determine the location and magnitude of imbalance.

What happens if balance adjustment is not performed?

If balance adjustment is not performed, machine life is shortened, energy consumption increases, product quality decreases, excessive noise and vibration occur, and serious safety risks may arise.

What is the difference between static and dynamic balancing?

Static balancing eliminates mass imbalance in a single plane, while dynamic balancing corrects mass imbalances in multiple planes. Dynamic balancing is more comprehensive and necessary, especially for components rotating at high speeds.