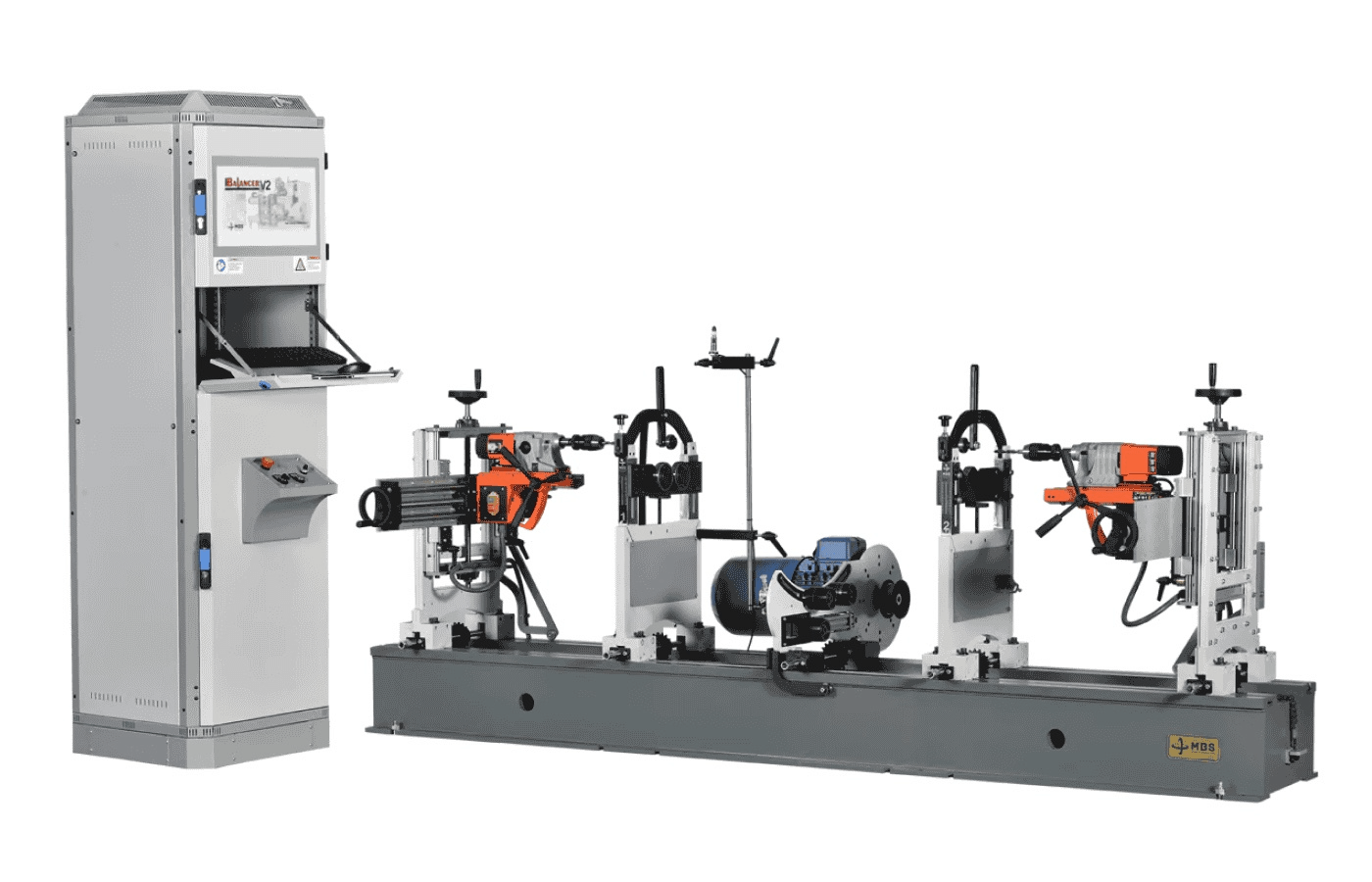

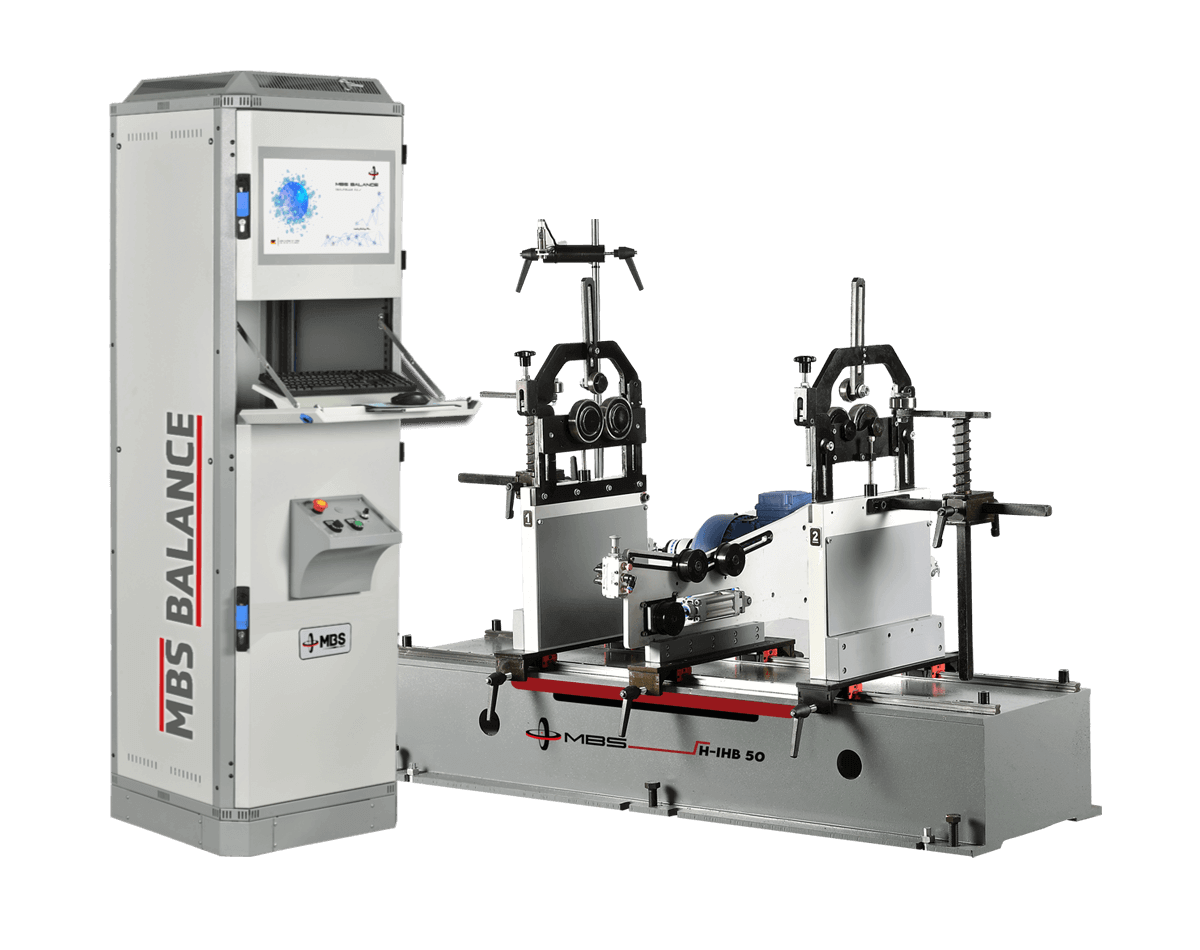

Industrial balancing machines are sophisticated systems that work to eliminate unwanted vibrations and mass unbalances in a rotating part. Their core operating principle is based on vibration measurement and force analysis. When a part is mounted to the machine and begins to rotate, any unbalance in the mass distribution creates a centrifugal force. This force causes the part and its bearings to vibrate. The balancing machine detects and measures these vibrations using high-precision sensors (transducers). The detected signal is then transmitted to the machine's control unit.

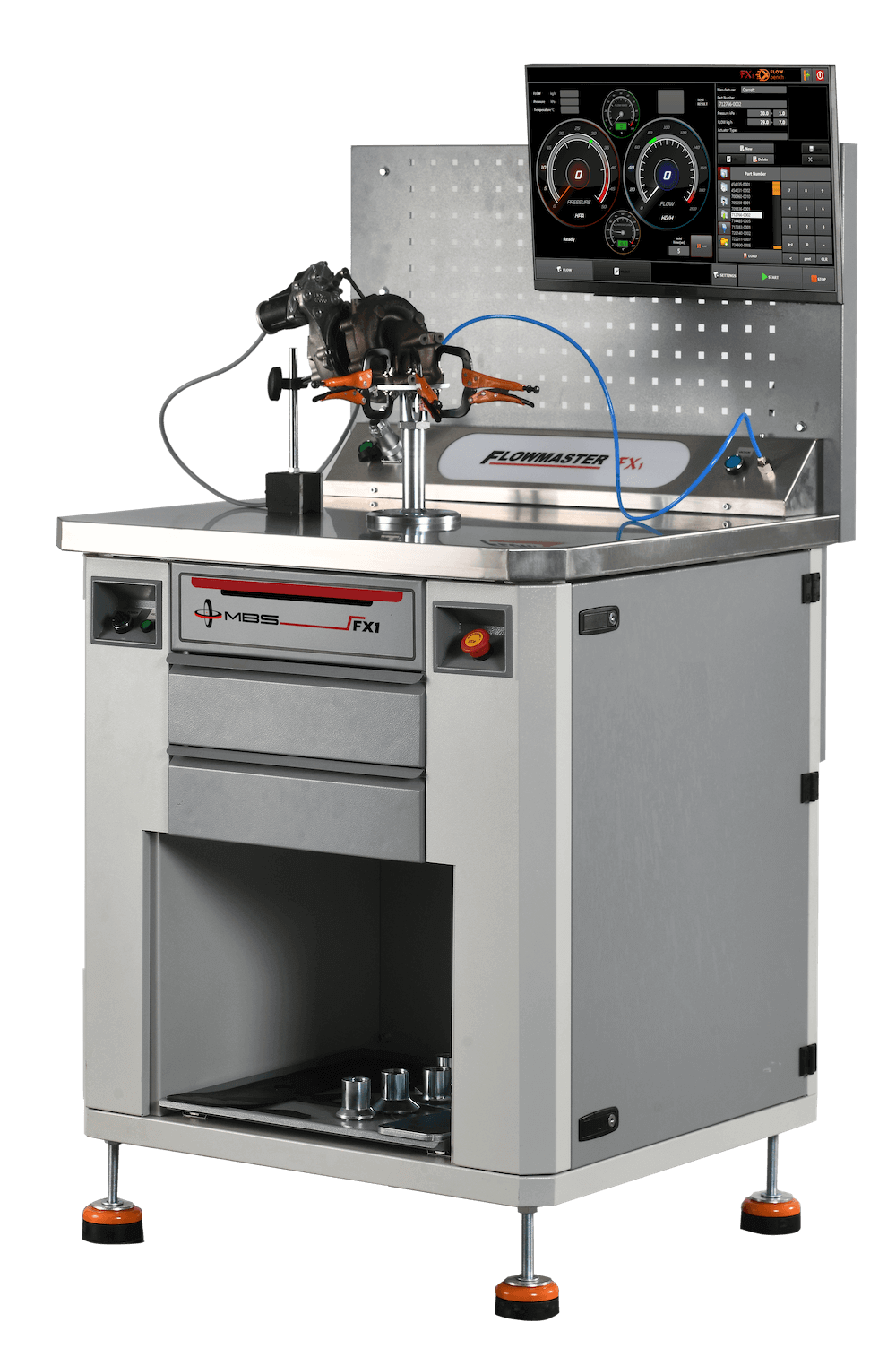

The advanced software within the control unit processes the data from the sensors and calculates the exact amount of the unbalance (in grams or ounces) and its angular position (in degrees). This data is clearly displayed to the operator on a screen. Based on this information, the operator determines the most suitable method to correct the unbalance (adding or removing weight). After the correction is complete, the part is tested again, and this cycle is repeated until the residual vibrations are reduced to an acceptable tolerance level. Specialized software like the iBalancer, developed by MBS Balans Sanayi, makes this process faster and more intuitive, minimizing operator errors and ensuring the highest precision.